Aethorion AI

Aethorion AI

Aethorion AI

Aethorion AI

Turn complex chemistry into your greatest competitive edge.

Bring groundbreaking designs to market at unprecedented speed.

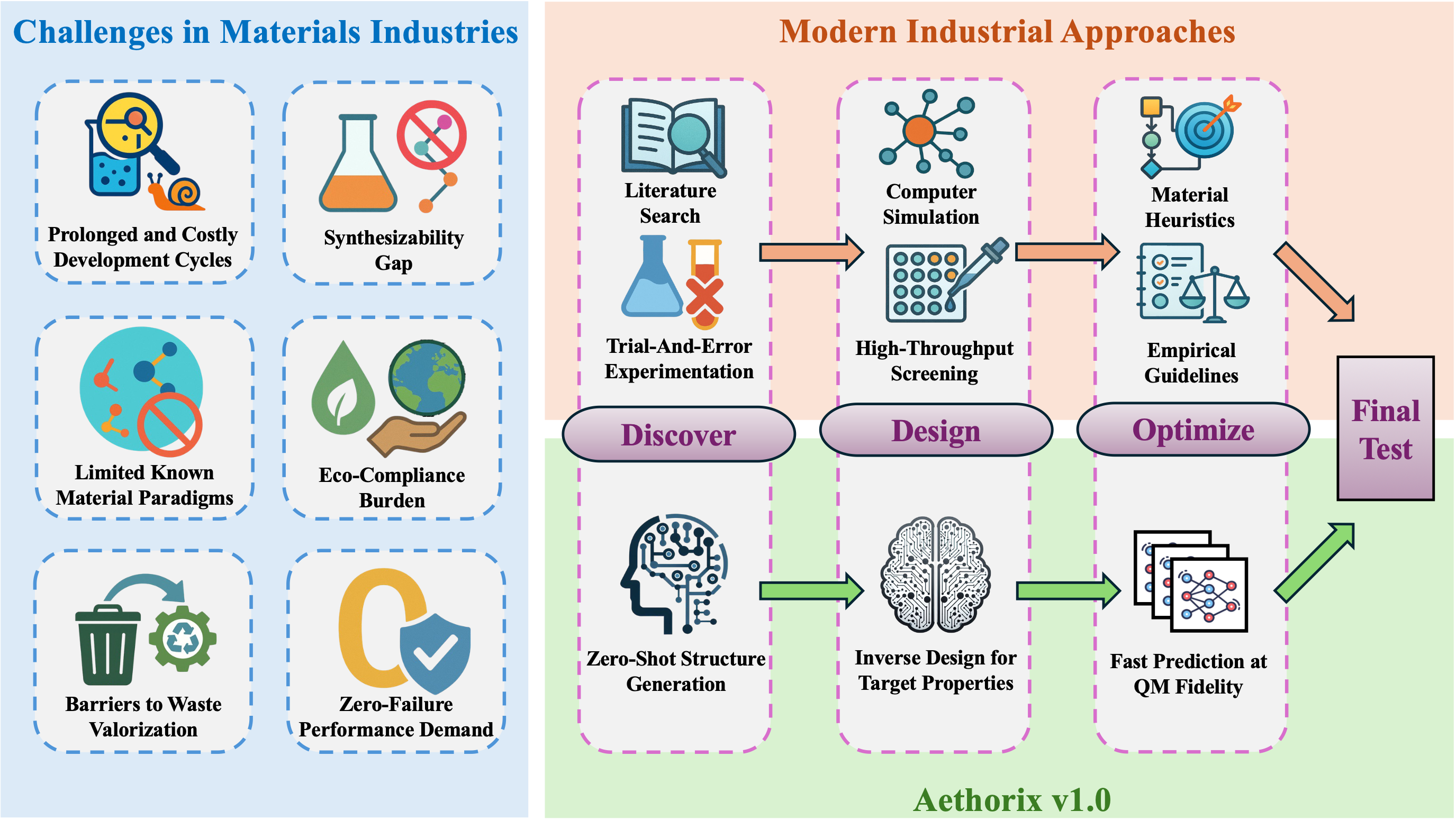

We revolutionize the future of chemical and materials industries with cutting-edge generative AI.

Our mission is to reduce prolonged go-to-market cycles of novel advanced materials from decades to months.

Discovery cycles are shortened from years to months.

Process parameters are optimized and adapted to match production pace.

Products are designed with proven cost and manufacturability from the start.

Explore the four core capabilities that converge into an AI unlike anything before.

We share the mission to spark humanity's next great leap.

Stay informed about our latest achievements and developments!

We launched Aethorix v1.0 to introduce our breakthrough solutions to the chemical and materials industry!

The co-founders won the second prize in the 2025 Sustainability In Action (SIA) Business Competition!

Are legacy approaches slowing your progress? It's time to embrace the transformation! Let Aethorion AI propel your organization into the next era of intelligence!